Demo Room Guide

Processing Experiments Using Spectronix Products

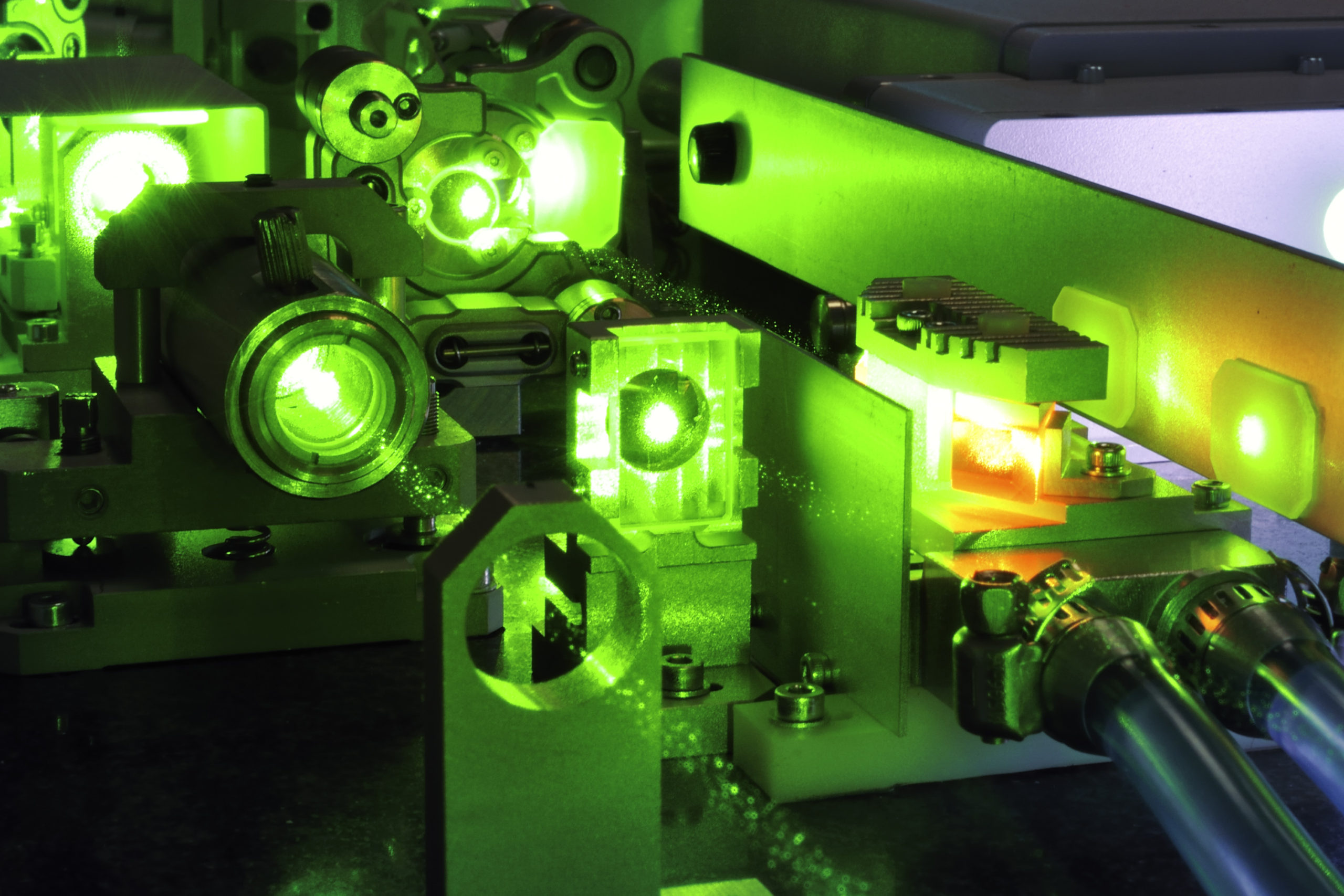

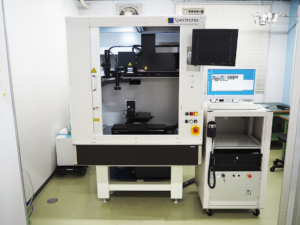

The demo room offers test processing machines equipped with picosecond lasers, galvanometers, optical systems, and XYZθ axes. Our laser process engineers will listen to your requests and provide maximum support to help create optimal processing conditions for installing equipment.

- Terms of Use

- Reservation Required

- Hours

- Weekdays (Monday to Friday) 10:00 a.m. to 5:00 p.m.

- Products for Experiments

- ・266 nm (DUV) picosecond hybrid laser ( LDH-X0810 ) ☆ The only one of its kind in the world!

- ・355 nm (UV) picosecond hybrid laser ( LDH-V1610 )

- ・532 nm (Green) picosecond hybrid laser ( LDH-G2510 )

- Measuring Devices

- ・Olympus 3D Microscope(OLS4100)

- ・Nikon Stereoscopic Microscope

-

Typical Measurement Images (Metal Grooving)

Observe and measure the sample surface shape on the spot after laser processing to an accuracy of 1/10 um.

Information on Paid Processing Experiments

☆ Paid processing experiments using picosecond lasers (Spectronix is the only company in the world that can perform processing experiments using a high-output 266 nm picosecond device!)

Processing experiments in the demo room are provided to customers considering installing picosecond laser processing equipment. Short-wavelength picosecond lasers of 266 nm, 355 nm, and 532 nm are installed for high-quality processing. Please feel free to contact us for more information.

Processing Experiment Flow

-

Contact Us

Fill out the inquiry or call us to make an inquiry.

Inquire about the demo room here -

Verify processing specifications

A sales representative will contact you. Please let us know the details of the process you wish to perform.

-

Prepare for the experiment and make an appointment

We will adjust the experiment schedule and prepare equipment based on when you are able to provide the materials to be processed.

-

Experiment

Observed Experiments

Customers may enter the demo room and observe the processing experiment.

Entrusted Experiments

Entrust your materials with us and we will return the processed product along with a report.

-

Results Reporting

We will provide a report that compiles enlarged images of the processed parts taken with a laser microscope as well as 3D data.

-

Recommendations

We will recommend solutions and the ideal laser oscillator for you based on the results of the processing experiment.